HolyCrapItsFast

Drinks beer!

In this write up I will attempt to explain the purpose of a Bypass Valve/Blow Off Valve (BPV/BOV) and what the differences are and how and when one should be used over the other. I will attempt to shed light on the pros and cons and dispel some misconceptions. We will also discuss some tuning options and provide a guide for selection.

Before I continue with this section I will say this statement first… It is through many years of findings and real world experience, by many members of the STi community, that you should not replace your BPV unless you have a definite need to do so. Because you want a cool sound is not a good reason. The induction system in a Subaru engine is precisely designed and making changes to this system with out clear purpose is counter intuitive. You absolutely get the best performance from the stock BPV on a stock car with a stock turbo. Other mods may require you to upgrade to an after market unit but you will need to choose wisely. Please read on...

1) What is a Bypass Valve (BPV) or Blow Off Valve (BOV)

A BPV/BOV is a valve that is placed in the air induction system of an engine and is specifically located after the outlet of the turbo and before the throttle plate and intake manifold. In the Subaru it is generally placed on the outlet end tank on the intercooler which is just before the throttle body.

A BPV/BOV is meant to relieve excess pressure after the turbo as the throttle plate is shut rapidly to prevent excessive compressor surge or stall. Here is a good explanation of compressor surge in section 1.1 of this paper http://www.gmrc.org/documents/GMRCSurgeGuideline_000.pdf. Compressor surge can be damaging to a turbo and significantly decrease its life. By relieving the pressure you reduce this effect significantly.

Some beneficial side effects of employing a BPV/BOV in the design of an engine is noticeably less compressor speed deltas, which means the turbo will remain spooled longer because you don’t have pre-conceived pressures backing up against the turbine blades. You also get smoother shifting.

2) What is the difference between a BPV and BOV.

Both valve types do exactly the same thing with one significant and important difference.

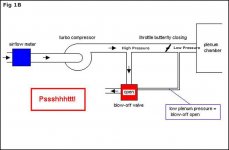

A BPV releases pressure and circulates it back to the turbo inlet after the MAF sensor. It is circulating air that has already been metered by the ECU. See Fig 1A.

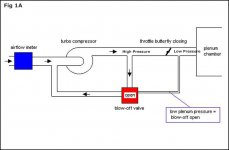

A BOV releases pressure out to the atmosphere which is were the so called “cool” sound comes from. See Fig 1B.

A hybrid is a combination of the two. It circulates 50% of the pressure back to the intake and 50% of the pressure to atmosphere. This minimizes the effects of a BOV on a system designed for a BPV while maintaining the cool sound of a BOV. If you must have a BOV for the sound then this is the preferred method.

3.0) BPV/BOV usage

As previously stated there should not be a reason to change out the stock BPV for most applications. However in some cases where high pressure and high volumes of air are being used, an aftermarket valve is in order.

The stock valve is a great valve. It is highly responsive and one of the most precise and well constructed BPV’s out. However it does have a limit. In high boost applications it can begin to fail and leak pressure at boost levels as low as 18-19psi. This is rare but it does happen. If you plan on running boost much beyond 20 psi then it is a good idea to change out your stock BPV for an aftermarket BPV/BOV. And No… The Ebay BPV/BOV’s are not adequate. Don’t skimp here because this is a device meant to save your turbo.

You may want to consider obtaining a valve with some kind of adjustment or replaceable spring. This will allow you to tailor the valve specifically to your application. Adjusting the BPV/BOV is a simple process.

You would start out at the lowest possible setting and drive around. You will want to drive using rapid throttle deltas and you want to shift allot. Take note and observe how smooth shift transitions are and watch for stalling during shift. One way to check for this is to go WOT in third gear and suddenly let off the gas and depress the clutch at the same time. If the engine reverts to a smooth idle quickly and does not stall you are good and probably require no more adjustment. If it stalls then you need to increase the spring pressure of the BPV/BOV.

If it does not stall but shifting is not smooth then you need to find a balance between good pressure release and shifting by increasing the spring pressure. You may begin to observe a slight degree of compressor surge but a small amount will not hurt the turbo. In fact some surge is desired on some applications were spooling the turbo takes time, such as in systems with front mount intercoolers and very large turbo applications, you want there to be some degree of pressure to remain in the system to minimize these effects.

Before I continue with this section I will say this statement first… It is through many years of findings and real world experience, by many members of the STi community, that you should not replace your BPV unless you have a definite need to do so. Because you want a cool sound is not a good reason. The induction system in a Subaru engine is precisely designed and making changes to this system with out clear purpose is counter intuitive. You absolutely get the best performance from the stock BPV on a stock car with a stock turbo. Other mods may require you to upgrade to an after market unit but you will need to choose wisely. Please read on...

1) What is a Bypass Valve (BPV) or Blow Off Valve (BOV)

A BPV/BOV is a valve that is placed in the air induction system of an engine and is specifically located after the outlet of the turbo and before the throttle plate and intake manifold. In the Subaru it is generally placed on the outlet end tank on the intercooler which is just before the throttle body.

A BPV/BOV is meant to relieve excess pressure after the turbo as the throttle plate is shut rapidly to prevent excessive compressor surge or stall. Here is a good explanation of compressor surge in section 1.1 of this paper http://www.gmrc.org/documents/GMRCSurgeGuideline_000.pdf. Compressor surge can be damaging to a turbo and significantly decrease its life. By relieving the pressure you reduce this effect significantly.

Some beneficial side effects of employing a BPV/BOV in the design of an engine is noticeably less compressor speed deltas, which means the turbo will remain spooled longer because you don’t have pre-conceived pressures backing up against the turbine blades. You also get smoother shifting.

2) What is the difference between a BPV and BOV.

Both valve types do exactly the same thing with one significant and important difference.

A BPV releases pressure and circulates it back to the turbo inlet after the MAF sensor. It is circulating air that has already been metered by the ECU. See Fig 1A.

A BOV releases pressure out to the atmosphere which is were the so called “cool” sound comes from. See Fig 1B.

A hybrid is a combination of the two. It circulates 50% of the pressure back to the intake and 50% of the pressure to atmosphere. This minimizes the effects of a BOV on a system designed for a BPV while maintaining the cool sound of a BOV. If you must have a BOV for the sound then this is the preferred method.

3.0) BPV/BOV usage

As previously stated there should not be a reason to change out the stock BPV for most applications. However in some cases where high pressure and high volumes of air are being used, an aftermarket valve is in order.

The stock valve is a great valve. It is highly responsive and one of the most precise and well constructed BPV’s out. However it does have a limit. In high boost applications it can begin to fail and leak pressure at boost levels as low as 18-19psi. This is rare but it does happen. If you plan on running boost much beyond 20 psi then it is a good idea to change out your stock BPV for an aftermarket BPV/BOV. And No… The Ebay BPV/BOV’s are not adequate. Don’t skimp here because this is a device meant to save your turbo.

You may want to consider obtaining a valve with some kind of adjustment or replaceable spring. This will allow you to tailor the valve specifically to your application. Adjusting the BPV/BOV is a simple process.

You would start out at the lowest possible setting and drive around. You will want to drive using rapid throttle deltas and you want to shift allot. Take note and observe how smooth shift transitions are and watch for stalling during shift. One way to check for this is to go WOT in third gear and suddenly let off the gas and depress the clutch at the same time. If the engine reverts to a smooth idle quickly and does not stall you are good and probably require no more adjustment. If it stalls then you need to increase the spring pressure of the BPV/BOV.

If it does not stall but shifting is not smooth then you need to find a balance between good pressure release and shifting by increasing the spring pressure. You may begin to observe a slight degree of compressor surge but a small amount will not hurt the turbo. In fact some surge is desired on some applications were spooling the turbo takes time, such as in systems with front mount intercoolers and very large turbo applications, you want there to be some degree of pressure to remain in the system to minimize these effects.

Attachments

Last edited: