Td_d

Commander In Chief

YES!

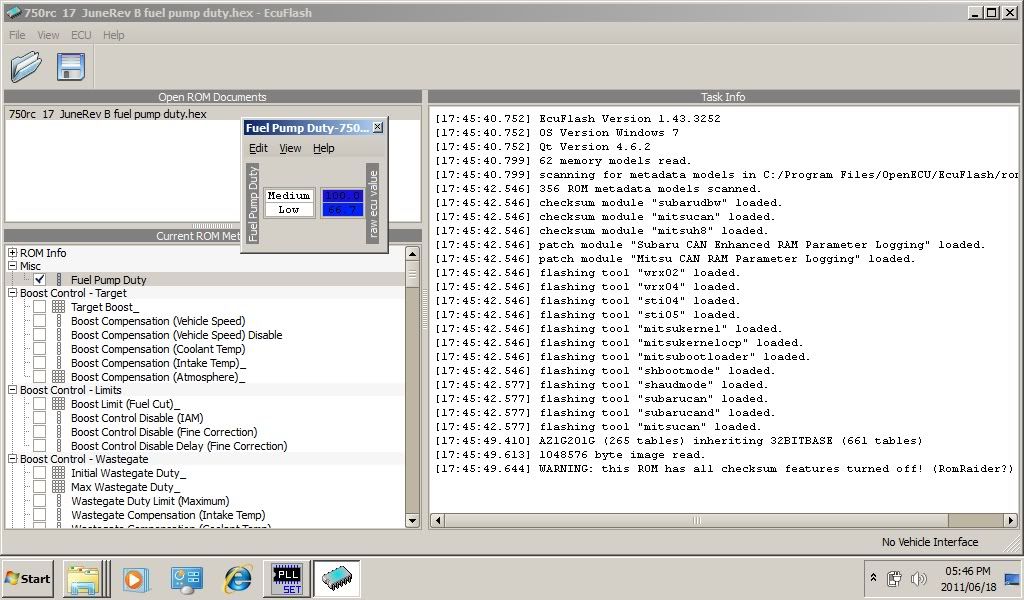

With a little bit of lateral thinking, some well postioned and acquired serial connectors, and a whole lot of reading - I now have wideband logging, stand-alone to the SD card, in CAN mode! And I didn't even need to splice open an OBD2 extension cord (which is on its way from the States soon) - which means I can use the cable as it is intended, to move the Tactrix away from the footwell, and reduce strain on the ECU harness.

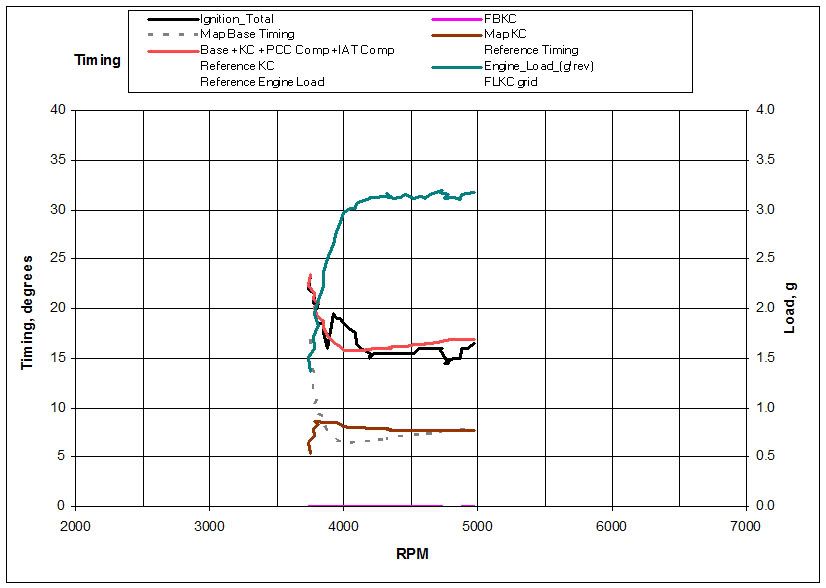

The resolution is amazing... 8 to 9 times the data compared to K-line, gives you a very detailed picture of what exactly is happening in WOT (the datapoints are about 30-50 RPMS apart).

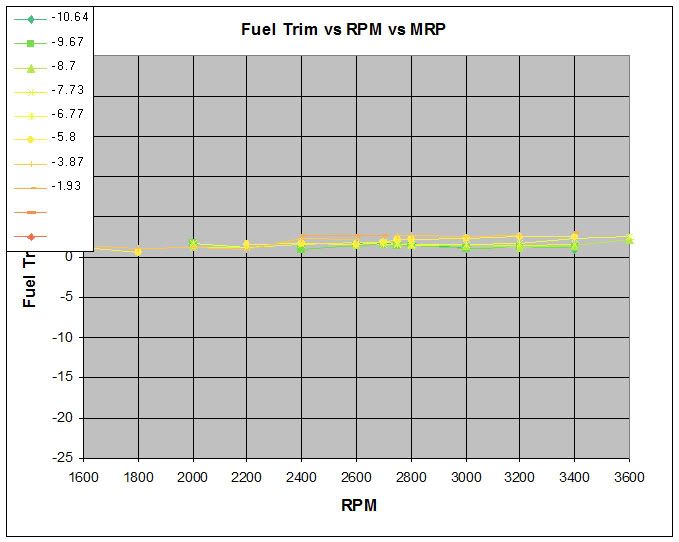

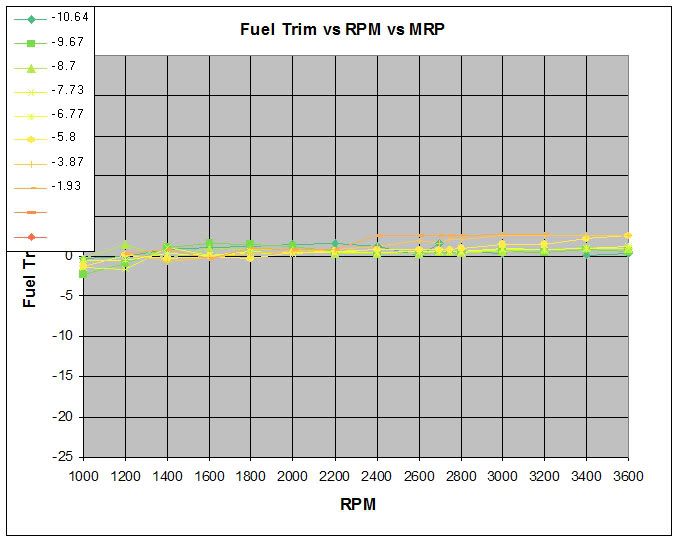

I'm also happy to report that the AFRs are nice and clean - dropping from the 12's in the upper 2000's, and down to target by 3200 as the turbo is spooling up - and then holding target quite neatly at 11.5 all through, as the meth / water mix is spraying.

I'm stoked!

With a little bit of lateral thinking, some well postioned and acquired serial connectors, and a whole lot of reading - I now have wideband logging, stand-alone to the SD card, in CAN mode! And I didn't even need to splice open an OBD2 extension cord (which is on its way from the States soon) - which means I can use the cable as it is intended, to move the Tactrix away from the footwell, and reduce strain on the ECU harness.

The resolution is amazing... 8 to 9 times the data compared to K-line, gives you a very detailed picture of what exactly is happening in WOT (the datapoints are about 30-50 RPMS apart).

I'm also happy to report that the AFRs are nice and clean - dropping from the 12's in the upper 2000's, and down to target by 3200 as the turbo is spooling up - and then holding target quite neatly at 11.5 all through, as the meth / water mix is spraying.

I'm stoked!